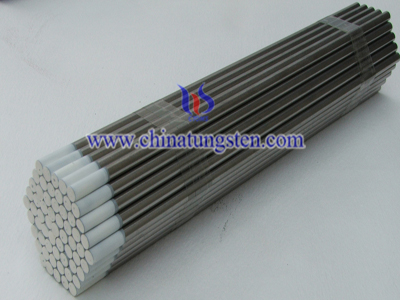

Cerium Tungsten Electrodes

Cerium tungsten electrodes are tungsten electrodes with 2% CeO2, which are non-radioactive materials. They are widely used in low amperage and require only about 10% less amps to operate than thorium tungsten electrodes. cerium tungsten electrodes can both used in DC and AC welding.

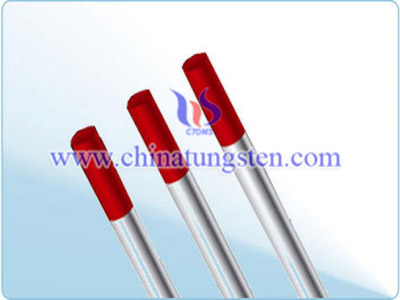

| Code | Impurity | Impurity Content | Tungsten | Tip Color | Electric Discharged Power |

| Wc20 | CeO2 | 1.8-2.2% | The Rest | Grey | 2.7 to 2.8 |

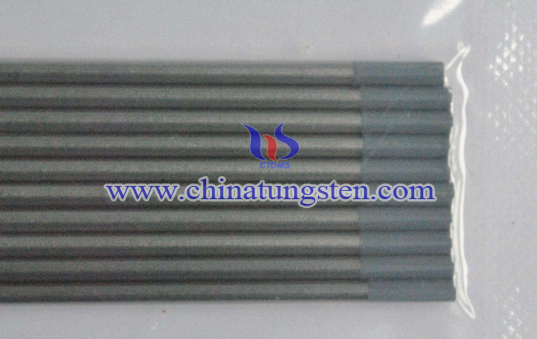

The power of cerium tungsten electrodes electronic transgression is 2.4ev, less than that of thorium-tungsten electrode. Its arc derivation voltage is also lower with better arc derivation function and higher arc power stability. The current allowed under the condition of anode direct current is higher and the burn spoilage is smaller.

Cerium is the most abundant of the rare earth elements and fund in number of minerals including allanite, monazite and bastnasite. For extracting Cerium, a process called ion exchange is used which uses monazite sands as the source of Cerium.

Cerium has a wide application across various industries. In the process of making stainless steel, Cerium is used as a precipitation hardening agent. Cerium is also used for alloying tungsten electrodes--cerium tungsten electrodes-- for gas tungsten arc welding. In glass manufacturing, this element is used both as a component and as a decolorizer which makes the production of industrial glass more effective.

Combine tungsten with cerium to make electrodes have been replacement for thorium tungsten electrodes in DC welding.