Cerium Tungsten Electrodes in TIG Welding

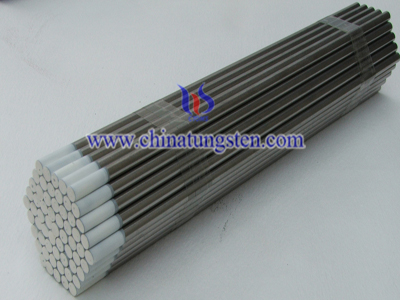

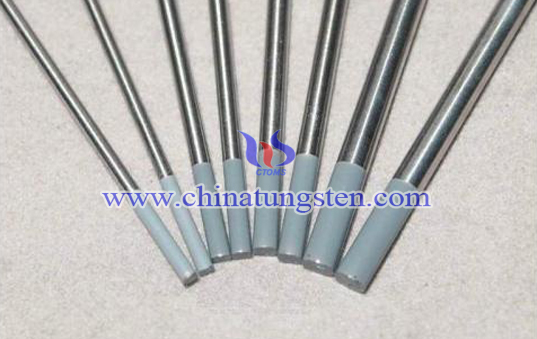

TIG is the acronym for tungsten inert gas, a type of welding that uses non-consumable tungsten electrodes, which are wear tolerance. cerium tungsten electrodes are tungsten electrodes and suitable for low amperage welding. Unlike the electrodes used for stick welding and the filler wire used for metal inert gas (MIG) welding, tungsten electrodes don’t melt and become part of the weld it self. But they are all fusion welding techniques that involve using heat to join metals.

There’s another name for TIG welding in the industry, gas tungsten arc welding (GTAW). The gas referred to in both its names is an inert gas mixture that protects the arc as well as the molten weld pool and the HAZ, which is the heat-affected zone right next to the weld. That’s the part right next to the weld puddle that gets really hot while you are welding then cools creating the HAZ. This gas provides a kind of blanket over the weld that stops porosity from forming and impurities and oxygen from getting into the weld witch would lead to potential failure. During welding, cerium tungsten electrodes can be used.

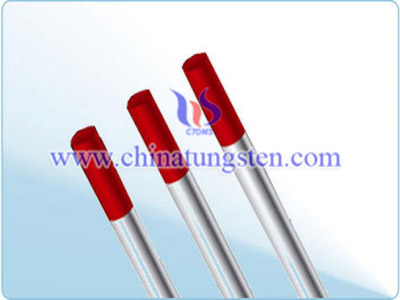

TIG welding electrodes usually contain small quantities of metallic oxides which can offer the following benefits:

Facilitate arc startingIncrease arc stability

Improve current carrying capacity of the electrode

Reduce the risk of weld contamination

TIG Welding (GTAW)

When used cerium tungsten electrodes in TIG welding, they can bear low current welding and have an easy starting arc.