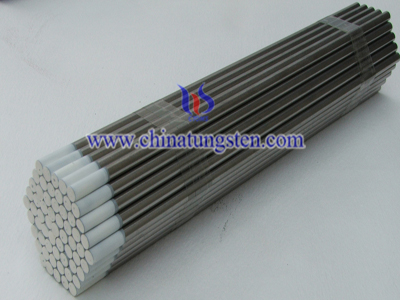

Tungsten Cerium Electrodes

Tungsten cerium electrode in the early 80's of the twentieth Century was introduced to the United States, as a non radioactive thorium tungsten electrode to replace tungsten. Cerium oxide cerium tungsten electrode usually contains 2%. It is well known that the cerium tungsten electrode at low voltages, suitable for DC welding, because of easy arc starting at a low voltage, 10% lower than the thorium tungsten at work. Cerium tungsten electrodes used for welding of pipeline is the most popular, is also usually used for welding of small parts. Compared with the pure tungsten electrode, the cerium tungsten electrode has a lower rate of combustion or evaporation rate. With the cerium content increased, these advantages can improve.

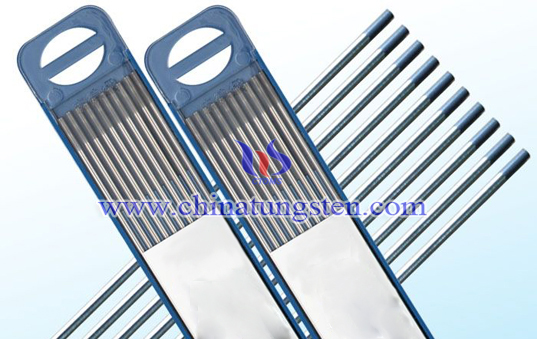

Cerium has the highest mobility, and thus the time at the start of welding, the welding performance is very good. Over time, due to grain growth, migration rate will be significantly reduced. However, at a low voltage, and longer life than the thoriated tungsten electrode. It is because of these characteristics, tend to favor short-cycle welding or soldering specific amount before you can replace the electrode. High current, voltage tungsten electrode welding is best to use thorium or lanthanum tungsten electrodes.

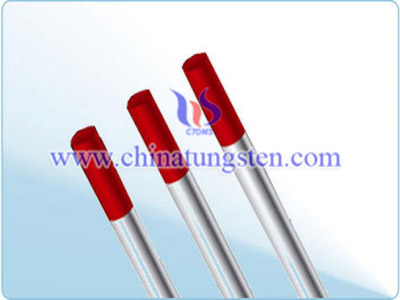

Tungsten cerium electrodes (EWCe-2) used successfully in a DC or AC, but is mainly used for DC welding, AC welding because the tungsten electrode is apt to cleave cerium.