Tungsten Electrodes Category

Tungsten Electrodes Category

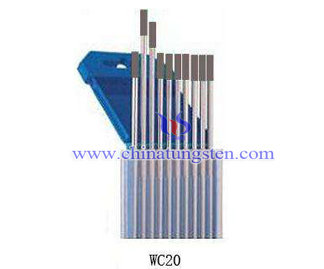

Ceriated Tungsten Electrodes:

Ceriated tungsten electrodes include varying percentages of cerium and also have been designed to work on both air conditioning and DC currents. Ceriated tungsten welding electrodes come with an addition of around 2% cerium oxide (CeO2) which helps you to reduce welding electrode burn-off. Within performance, the ceriated welding electrode will react similar to pure tungsten by giving a stable arc and reducing the quantity of tungsten “spitting”. These characteristics permit this welding electrode to do well on aluminum in balanced influx machines (A. D.) and on steel within the D. C. setting.

Pure Tungsten Electrodes:

Pure tungsten electrodes aren’t often recommended or employed for A. C. welding upon aluminium and magnesium other metals as Zirconiated, and Ceriated electrodes possess gained popularityin modern times. Pure Tungsten electrodes contain no less than 99. 5% tungsten, without any alloying elements deliberately added. By utilizing high purity tungsten, present carrying capability is actually diminished, although this maintains a thoroughly clean, balled end which supplies good arc balance.

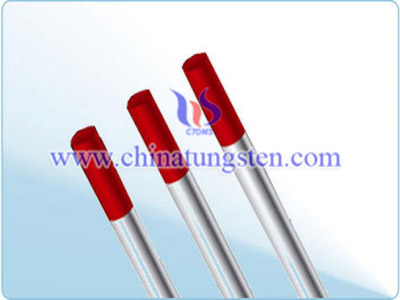

Zirconiated Tungsten Electrodes:

Zirconiated tungsten welding electrodes possess arc stability characteristics that act like pure tungsten form higher current carrying capability present in the thoriated tungsten. This welding electrode supplies a good balance associated with properties. It is actually more resistant in order to contamination than real tungsten and much better for radiographic-quality welding programs than thoriated tungstens.

Besides what have introduced above, tungsten electrodes still have thoriated tungsten electrodes, yttriated tungsten electrodes and composite tungsten electrodes. Cerium tungsten electrodes have 0.1 cerium tungsten electrodes and 0.2 cerium tungsten electrodes.